It’s beginning to seem that the entire world is going green. With the Lura Screed, and its line of pervious concrete finishing tools, you’ll be ready to grow your own green business. Pervious concrete, also known as “No Fines” or “Permeable” concrete, allows water to flow through it, making it ideal for storm water run-off control and earning LEED certification in most cases.

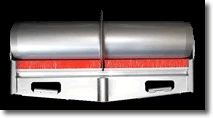

Lightweight: Because it can be filled with water, Lura Screed is ideal when pouring pervious concrete. Each aluminum section weighs only 4.5 lbs. and reaches 11 lbs. when filled with water, giving it ideal compressive weight. This eliminates the need for sandbags or the addition of any extra weight; and because Lura Screed is 1/3 of the weight of most competitor units, our system greatly reduces the risk of crew injuries.

.jpg)

It’s important for contractors to recognize that the weight of the screed itself doesn’t matter. Rather, it’s the compressive weight of the system that makes a unit successful. As long as the screed tube is resting on the forms and not floating, crews can’t apply more pressure because the form will resist. Because it stays on the forms, the Lura Screed system applies more pressure than competitor units because it stays on the forms.

Exceptional Cutting Ability: But don’t think that lightweight translates to light work. Lura’s unique design provides exceptional cutting ability making it a true workhorse. The riser wheels eliminate friction and make it easier to pull while its unique design and extraordinary cutting ability eliminate all unnecessary manpower.

Because pervious pours are done by panel, riser wheels allow for more convenient application during fill-ins. The riser wheels ensure that the only friction that exists is from the wet pervious concrete, not the screed itself. This eliminated friction translates to an easy to use system for virtually any operator.

Durable: Roller screeds are widely viewed as the best method to strike pervious concrete to avoid consolidating and is recommended by the NRMCA. The Lura Screed system compresses the pervious concrete, tightens the aggregate, and enhances the strength and durability of the pervious concrete.

.jpg)

The following are accessories that enhance the success of pervious pours.

The Cross Roller: This roller is designed primarily for compaction and is used to create a more durable wear surface. It’s applied as soon as the pervious concrete is leveled. We’ve learned from years of experience that the right way to place pervious is by first, elevating the screed tube, and then rolling it down with the cross roller to compact the top surface. This process is simple and effective.

The Joint Cutter: The Joint Cutter, a weighted roller with a cutting wheel, is used to put control joints into the pervious concrete soon after the Cross Roller is used. This prevents cracking in weak areas. Custom cutters are available upon request to suit various thickness requirements.

Adjustable Curb Runner: If pervious is being poured up against a sidewalk or a curb, the adjustable curb runner might be necessary. Lura’s patented threaded axle design gives crews the flexibility to be right up against the edge, eliminating a great deal of the hand finishing work that competitor systems leave behind.

Painter’s Plastic: Lura incorporates painter’s plastic into their pervious curing process. We do all the work – cross rolling and joint cutting over this plastic immediately after the concrete is struck off. This method saves time and money while also increasing the success rate of the pour. With pervious concrete, it’s hugely important to get the poured concrete covered as quickly as possible. The thin nature of the painter’s plastic allows it to stick to the cement paste, creating a vacuum seal effect. As an added security measure, our team recommends placing 6-mil over the painter’s plastic. The 6-mil is there to protect the painter’s plastic and ensure a proper concrete cure.